From the bulky cast-iron pressure vessels of the 19th century to today’s efficient stainless steel pressure cookers, the kitchen tool evolution reflects leaps in material science and engineering, as well as humanity’s relentless pursuit of safety and efficiency. As a professional stainless steel pressure cooker manufacturer, Linkton is committed to providing high-quality stainless steel pressure cooker solutions to customers. This article will take you through the stainless steel pressure cookers and explain how Linkton leads the new trend.

Origins: A Culinary Revolution Born from the Industrial Age

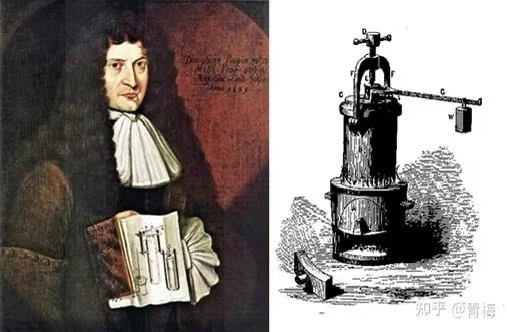

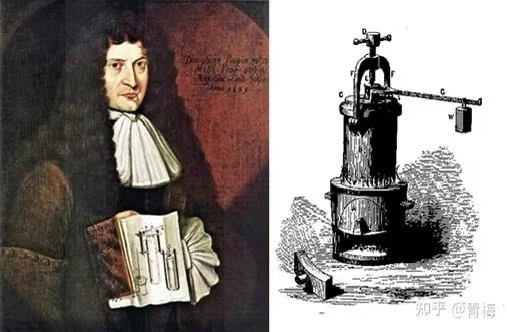

In the 1830s, French physicist Denis Papin invented the world’s first “steam digester,” using a sealed container to raise boiling points and accelerate food softening. Though its cast-iron design was too heavy and unsafe for widespread use, it laid the foundation for pressure cooker principles.

By the 1930s, the Aluminum Company of America introduced the first aluminum pressure cooker for households. Its lightweight design brought it into homes, but issues like oxidation, uneven heat distribution, and frequent safety incidents soon emerged.

Turning Point: The Dawn of the Stainless Steel Era

In the 1970s, advancements in metallurgy led to the application of 304 stainless steel in cookware. Compared to aluminum, three advantages of stainless steel revolutionized the industry:

Corrosion Resistance: Withstands acids and alkalis, extending lifespan.

High-Temperature Stability: Melting point exceeding 1400°C, eliminating deformation risks

Health Safety: Prevents aluminum ion leaching, meeting food-grade standards.

From the 1980s to the 2000s, European brands like Fissler pioneered ステンレス圧力鍋, but their high prices (around $300) limited them to premium markets.

Innovation: The Rise of Chinese Manufacturing and Linkton’s Technological Breakthrough

In 1996, Chaozhou Linkton Stainless Steel Products Co., Ltd. was founded, focusing on stainless steel pressure cooker R&D. At the time, the Chinese pressure cooker market was dominated by aluminum models plagued by safety issues.

By 2020, Linkton entered the pressure cooker sector, disrupting the industry with three core technologies:

Dynamic Sealing System: Elastic clamping beams and necking processes improved sealing by 40%, far exceeding national standards in pressure stability.

Quadruple Pressure-Release Protection: Layered safeguards including an 80kPa pressure valve, 120kPa safety valve, emergency vents, and debris filters, reduced accident rates to 0.001%.

Multi-Layer Base Technology: A 304 stainless steel outer layer, aluminum core, and polished inner surface boosted heat conductivity by 70% compared to pure stainless steel.

Market Impact: Linkton’s explosion-proof series sold over 500,000 units in Europe, the U.S., and Southeast Asia within its first year, achieving an 82% repurchase rate.

Present: Global Trends and Linkton Strategic Vision

Global Demand Insights

- Health-Centric Choices: 63% of consumers prioritize coating-free, food-grade stainless steel cookware (Euromonitor, 2023).

- Smart Integration: Demand for auto-pressure adjustment and app connectivity grows by 35% annually.

- Sustainability: Recyclable stainless steel products generate 58% lower lifecycle carbon emissions than aluminum.

Linkton’s Innovative Response

- Material Upgrade: Launched 316 medical-grade stainless steel series, offering 3x higher chlorine corrosion resistance for coastal regions.

- Smart Ecosystem: Debuted IoT-enabled pressure cookers in 2024 with built-in sensors and AI algorithms for optimized cooking curves.

- Green Manufacturing: Adopted hydrogen-powered electrolytic polishing, reducing carbon footprint by 40% and earning SGS carbon-neutral certification.

Future: From Kitchen Tool to Intelligent Health Guardian

McKinsey predicts the global smart kitchenware market will exceed $42 billion by 2030. Linkton is future-proofing through:

Health Monitoring: Embedded sensors analyze nutrient retention and optimize cooking methods.

Material Revolution: Partnering with CAS to develop nano-coated stainless steel with 99.9% antibacterial efficiency.

Global Service Network: R&D centers in Germany and the U.S. enable 48-hour global spare parts delivery.

結論

From imitation to leadership, from manufacturing to smart manufacturing, リンクトン embodies the resilience of Chinese brands over 27 years. Our ステンレス圧力鍋 are not just kitchen tools but symbols of safety, health, and efficiency.

As a practitioner and promoter of the pressure cooker revolution, リンクトン is willing to work with global partners to jointly develop a new era of efficient, safe and intelligent kitchens. Welcome to contact us for more information on our products and customized services.