Wholesale Pressure Cooker and Chafing Dish

As the best pressure cooker manufacturer and chafing dish supplier, Linkton produces and wholesale pressure cookers, chafing dishes, GN pans, and stainless steel trays. All products are made of premium stainless steel and have strict quality certification.

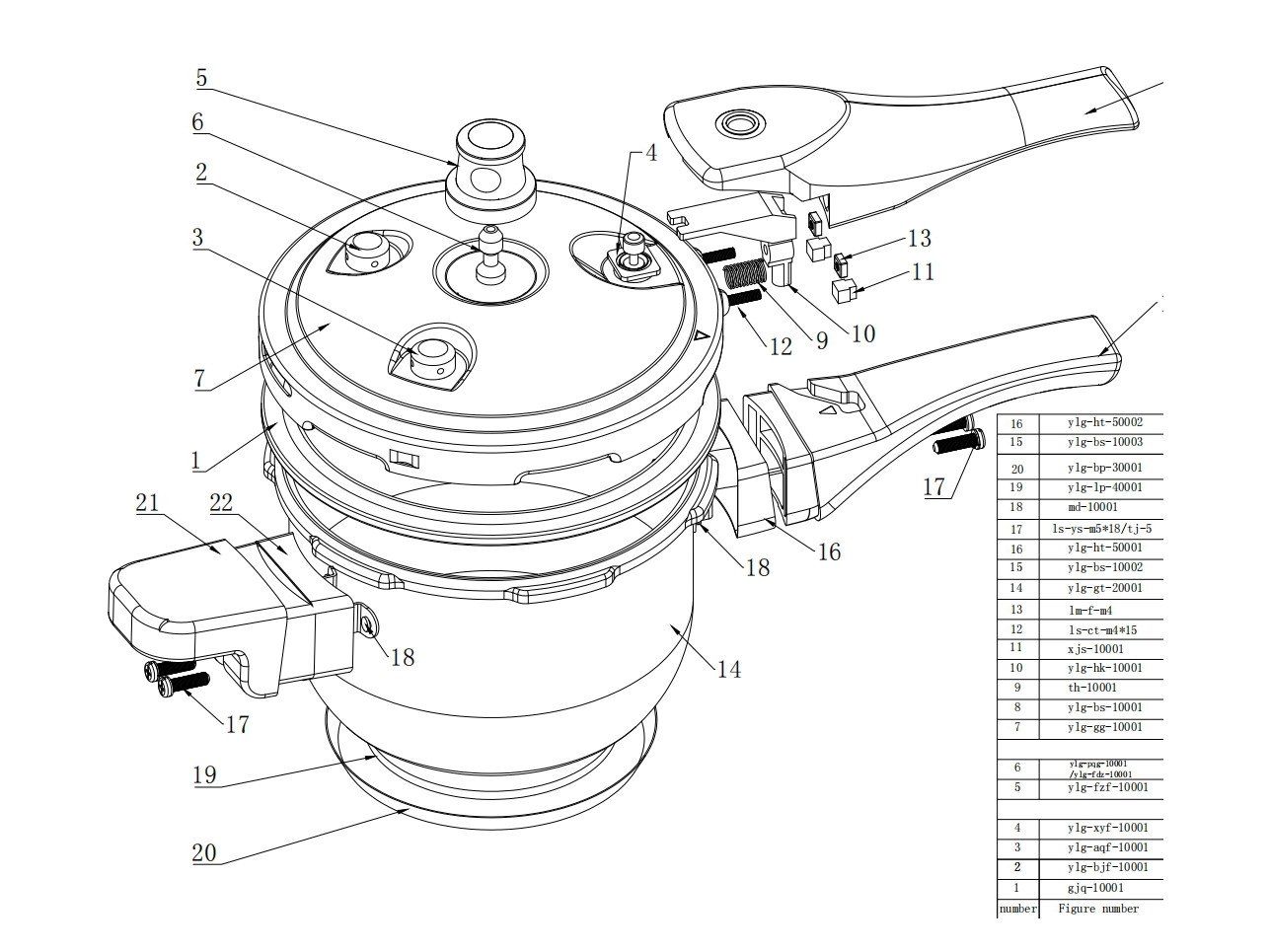

High Quality Combined with Safety Features

Multiple Shapes and Customization Options

Standard Full Size and Food Grade Material

Food Grade Materials and Various Specifications

Leading Pressure Cooker Manufacturer

Founded in 1996, Linkton is a Chinese pressure cooker manufacturer with mold R&D technology, focusing on excellent quality and service. Production and wholesale stainless steel pressure cookers, wholesale chafing dishes, GN pans, stainless steel trays, etc. Linkton cooperates with 100+ countries worldwide and has become the preferred pressure cooker and chafing dish supplier.

01

Quality Control System

Strict quality management system iso9001, control safety quality in every detail.

About Quality Control02

Mold Design & Development

Own mold design and production workshop, advanced equipment and innovation capabilities.

About Mold R&D03

Production Capability

30000 square meters of large-scale production plant, more than 30 professional production lines

About ProductionOne-Stop Custom Solution

Customize your brand from our wide range of options, whether it is custom pressure cookers, custom chafing dishes and other catering equipment supplies, we can realize your ideas!

Logo Customization

Accessories Custom

Color Customization

Size Customization

Packaging Customization

Shape Customization

Customer Support Center

Here, you can get complete customer service and technical support, from product manuals to Amazon FBA and all cooperation models, every step of the way our professional customer support center will help you!

Most Popular Pressure Cookers & Chafing Dishes Wholesale

Our experienced mold design team continuously innovates new multifunctional products, including stainless steel pressure cookers, chafing dishes, etc., leading the industry’s latest trend.

News & Blogs

Latest News, Tips, and Innovations in Pressure Cookers and Catering Equipment.

Your Trusted Pressure Cooker Manufacturer

and Chafing Dish Supplier

Focusing on product quality and safety, we provide high-competitive-priced pressure cooker wholesale and chafing dish custom solutions. We have a series of buffet equipment, and help your catering business succeed with high-quality products and excellent services.

Contact Us

To Get Pressure Cooker and Chafing Dish Wholesale Solutions with a Professional Team.

Follow Us